- CJ Series Jaw Crusher

- Sand Making Machine

- CCH Hydraulic Cone Crusher

- CCS Hydraulic Cone Crusher

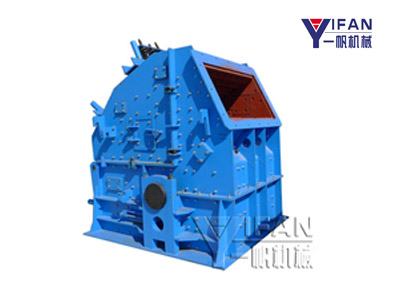

- CHP/CHS Impact Crusher

- CCM Hydraulic Cone Crusher

- Vertical Shaft Impact Crusher

- Gyratory Crusher

- Construction waste recycling

- Mobile Jaw Crusher station

- Crawler Screening Crusher

- Mobile Impact Crusher Station

- Mobile Screening Station

- Crawler Mobile cone Crusher

- Mobile Cone Crusher Station

- Crawler Mobile Impact Crusher Station

- Vertical Impact Mobile Crusher

- Crawler Mobile VSI impact crushing plants

- Mobile Teeth Roll Crusher

CHP/CHS Impact Crusher

Feed size: 700mm. production capacity :30-850t / h.

Crushing materials: granite, limestone, concrete, lime, gypsum, slaked lime.

Applications:Widely used for crushing various soft and medium hard ore, primary crushing and secondary crushing coarse broken, broken, broken bits. Mainly used for mining, construction, chemical, cement, metallurgy and other industries.

CHP (A) / CHS (A) series impact crusher in absorbing foreign advanced technology and optimized design combined with the actual situation, the overall structure is simple and practical, yet reasonable, more humane, while cavity greater and moreexcellent, under the same conditions, improve production efficiency.

CHP (A) / CHS (A) series impact crusher is widely used for crushing various soft and medium hard ore, primary crushing and secondary crushing rough broken, broken, broken bits. Mainly used for mining, construction, chemical, cement, metallurgy and other industries.

CHP (A) / CHS (A) series impact crusher features are as follows:

1, high-quality sheet metal and wear parts, reducing wear and tear, improve conditions of production efficiency; advanced processing technology and processes, is the basis of equipment performance.

2, Product versatility, the two chamber crushing equipment in replacement of other parts of the foundation to increase the grinding holder, you can become a three-chamber crushing equipment, reduce user secondary investment.

3, heavy-duty rotor, finite element stress analysis, optimal design, the structure is more reasonable, the moment of inertia of a larger, more broken than crushing capacity, abrasion resistance.

4, rotor welding process, prior to assembly to be done to static and dynamic balance test, so that the rotor running more smoothly, use longer.

5, Spindle quality forgings finishing at the same time the whole shaft key design, using state-of-the-art international expansion sets up tight connection, more reliable equipment operation, post-maintenance easier.

6, unique board hammer locking device, tightening torque larger, more secure, the board hammer replace it with a more simple, convenient and fast.

7, lining standardized design, strong interchangeability, and to reduce the types of user spare parts and inventory, and replacement easier.

8, a simple and practical locking means, the Impact Crusher housing a housing two tightly locked together. Such device operation is simple, convenient, and the locking time savings.

9, unique hydraulic device design, both user-friendly easily open rack, replacement parts, and can adjust the discharge opening counterattack frame.

10,the counterattack rack and the structural adjustment of the grinding holder is simple, easy to operate, difficult to damage, at the same time easy maintenance, and low cost.

CHP/CHS Impact Crusher Technical Data:

|

Model |

Max Feed edge(mm) |

Capacity(t/h) |

Motor power(kW) |

Weight(Excluding Motor)(t) |

|

|

with grinding cavity |

without grinding cavity |

||||

|

CHP4939(A) |

500 |

90-160 |

110-132 |

14.696 |

13.596 |

|

CHP4955(A) |

500 |

100-260 |

132-200 |

17.43 |

16.12 |

|

CHP5159Ⅱ(A) |

600 |

180-300 |

200-250 |

21.2 |

22.12 |

|

CHP5559(A) |

650 |

220-450 |

250-315 |

27.046 |

25.438 |

|

CHP5979(A) |

700 |

250-550 |

400-440 |

36.45 |

34.3 |

|

CHP6379(A) |

800 |

300-600 |

440-560 |

45.3 |

42.3 |

|

CHP7179(A) |

1000 |

500-850 |

630 |

84.1 |

78.9 |

|

CHP7998(A) |

1200 |

800-1200 |

1250 |

111.5 |

101.2 |

|

Model |

Max Feed edge(mm) |

Capacity(t/h) |

Motor power(kW) |

Weight(Excluding Motor)(t) |

|

|

with grinding cavity |

without grinding cavity |

||||

|

CHS4528(A) |

250 |

40-70 |

37-55 |

11.8 |

10.98 |

|

CHS4539(A) |

300 |

70-100 |

55-75 |

14.4 |

13.47 |

|

CHS4939(A) |

350 |

100-180 |

110-132 |

14.696 |

13.596 |

|

CHS4955(A) |

350 |

150-290 |

132-200 |

17.43 |

16.12 |

|

CHS5159Ⅱ(A) |

400 |

180-350 |

200-250 |

21.05 |

22.04 |

|

CHS5559(A) |

450 |

250-450 |

250-315 |

27.046 |

25.438 |

|

CHS5979(A) |

500 |

280-550 |

400-440 |

36.7 |

34.6 |

|

CHS6379(A) |

600 |

300-600 |

440-560 |

45.7 |

43.5 |

|

CHS7179(A) |

700 |

500-850 |

630 |

84.1 |

78.9 |

|

CHS7998(A) |

1000 |

700-1100 |

1250 |

115.6 |

109.5 |

Note:The capacity is total tons per hour passing through crusher at open circuit when crushing medium and below hardness material and bulk density with 1.6x10³kg/m³.Capacities are relative to physical character and type of feeding,feeding size and composition and so on.

Dear friends :

Welcome to Zhengzhou Yifan Machinery Co.,Ltd. To contact us through our website,

Please feel free to give your inquiry in the form below.We will reply you with details ASAP.

NEXT:CCS Hydraulic Cone Crusher