- CJ Series Jaw Crusher

- Sand Making Machine

- CCH Hydraulic Cone Crusher

- CCS Hydraulic Cone Crusher

- CHP/CHS Impact Crusher

- CCM Hydraulic Cone Crusher

- Vertical Shaft Impact Crusher

- Gyratory Crusher

- Construction waste recycling

- Mobile Jaw Crusher station

- Crawler Screening Crusher

- Mobile Impact Crusher Station

- Mobile Screening Station

- Crawler Mobile cone Crusher

- Mobile Cone Crusher Station

- Crawler Mobile Impact Crusher Station

- Vertical Impact Mobile Crusher

- Crawler Mobile VSI impact crushing plants

- Mobile Teeth Roll Crusher

CCH Hydraulic Cone Crusher

CCH series hydraulic cone crusher is the cone crusher developed after the absorption of the world advanced crushing technology with the advanced level, the more widely used in metallurgy, construction, utilities, transportation, chemical industry, building materials industry, suitable for crushing hard, medium hardness a variety of ores and rocks. SMH series hydraulic cone crusher is a high-performance cone crusher, will design speed and stroke, as well as crushing cavity optimized portfolio to achieve intergranular laminating crushing significantly improves yield and product shape is also greatly improved .

Hydraulic cone crusher features and technical advantages:

CCH Series high efficiency Hydraulic Cone Crusher has more advantages than the general hydraulic cone crusher:

1, large crushing ratio, high production efficiency- Higher speed and stroke combined, the rated power of the CCH crusher greatly improved, and by the ability to improve the crushing ratio and production efficiency. The hydraulic cone crusher crushing stroke, crushing speed and crushing chamber shape perfect combination of design, 35% to 60% higher than the old-fashioned spring cone crusher production.

2, less wearing parts consumption, low running costs- Reasonable structure, advanced crushing principle and technical parameters, reliable operation, low running costs; the crusher all parts are wear protection, reduce maintenance costs to a minimum useful life of more than 30% increase in the general.

3, pyramid broken, excellent grain shape finished- Through the use of special crushing chamber the laminate design principles intergranular and matched speed, replacing the traditional single particle crushing principle, to achieve selective crushing of materials, significantly increase the proportion of product fines and cube content, very large extent, reducing the pin sheet material.

4, the hydraulic protection and hydraulic cavity clearing, high degree of automation, reduce downtime- Hydraulically adjustable discharge opening and overload protection makes the the crusher operation level greatly improved, to make maintenance easier, more convenient operation, less downtime; the CCH series cone crusher bidirectional over iron release hydraulic cylinders allow the iron through crushing chamber, the aircraft happened Iron and instantaneous stuffy car can hydraulic roof, automatic nesting, greatly reduces the original spring cone crusher shutdowns required for artificial nesting troubles, and many other manufacturers of crusher but it will be the death of downtime due to excessive iron card.

5, rare lubrication, reliable and advanced to improve life- Unique thin oil lubrication system design, greatly improving the useful life of equipment. High performance non-contact labyrinth seals wear, improve the blocking dust reliability, and fundamentally eliminate the common failure of the original spring cone crusher oil water mix.

6, a variety of crushing cavity, flexible application, adaptable- CCH cone crusher is only necessary to replace the fixed cone lining, dynamic cone lining crushing chamber shape from the standard crude cavity to short head ultrafine cavity type any transform, to adapt to a wide range of product size requirements.

7, maintenance is simple, easy to use- CCH cone crusher all parts from the top or side of the disassembly and maintenance, easy disassembly of the moving cone and fixed cone not need disassembly rack, fastening bolts, thus CCH cone crusher daily replacement of the liner and more convenient. Use of hydraulic motors, and the top so that the production efficiency of the crusher.

8, which provides a higher production capacity, best product shape, and easy automatic control, with the greatest reliability and flexibility, true to create more value for users.

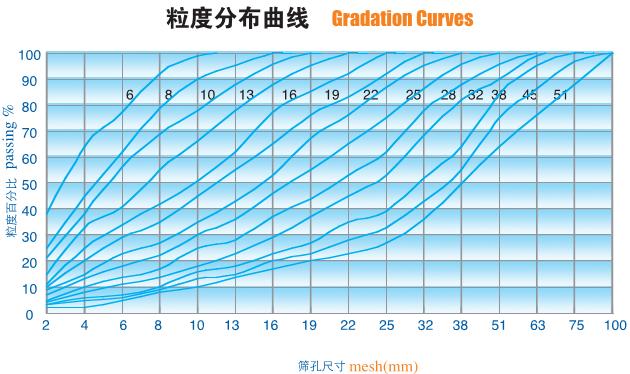

crushing material particles curve maps

crushing material particles curve maps

CCH Hydraulic Cone Crusher Technical Data:

| Model | Type of Cavity | Max Feeding Size(mm) | Discharge Range(mm) | Motor Power(kw) | Capacity(t/h)--open circuit, closed discharge(mm) | |||||||||||

| 9 | 13 | 16 | 19 | 22 | 26 | 32 | 38 | 51 | 63 | 76 | 89 | |||||

| CCH639 | C | 160 | 22-33 | 75-90 | 120 | 130 | 150 | |||||||||

| M | 130 | 13-26 | 65 | 85 | 100 | 120 | 130 | |||||||||

| F | 50 | 9-19 | 40 | 60 | 80 | 90 | ||||||||||

| CCH651 | EC | 260 | 26-51 | 185-200 | 250 | 290 | 340 | 395 | ||||||||

| C | 220 | 19-51 | 182 | 209 | 236 | 279 | 334 | 365 | ||||||||

| M | 150 | 16-38 | 125 | 140 | 165 | 220 | 275 | 330 | ||||||||

| F | 80 | 9-22 | 70 | 90 | 115 | 130 | 150 | |||||||||

| CCH667 | EC | 315 | 38-24 | 250-280 | 555 | 649 | 766 | |||||||||

| C | 230 | 26-64 | 366 | 430 | 468 | 629 | 657 | |||||||||

| M | 205 | 22-52 | 266 | 299 | 348 | 393 | 451 | |||||||||

| F | 180 | 16-38 | 188 | 212 | 234 | 267 | 305 | 337 | ||||||||

| CCH684 | EC | 450 | 38-89 | 400 | 890 | 1179 | 1380 | 1475 | 1566 | |||||||

| C | 350 | 32-76 | 800 | 850 | 1100 | 1288 | 1398 | |||||||||

| M | 320 | 26-63 | 612 | 735 | 815 | 990 | 1137 | |||||||||

| F | 268 | 19-52 | 376 | 412 | 500 | 620 | 725 | 867 | ||||||||

Technical Data of the Short head hydraulic cone crusher :

| Model | Type of Cavity | Max Feeding Size(mm) | Discharge Range(mm) | Motor Power(kw) | Capacity(t/h)--open circuit, closed discharge(mm) | |||||||||||

| 3 | 5 | 6 | 9 | 13 | 16 | 19 | 22 | 26 | 32 | 38 | ||||||

| CCH639D | C | 70 | 6-19 | 75-90 | 59 | 68 | 96 | 110 | 130 | |||||||

| M | 51 | 5-16 | 45 | 59 | 68 | 96 | 110 | |||||||||

| F | 35 | 3-13 | 30 | 45 | 50 | 65 | 90 | |||||||||

| CCH651D | C | 89 | 9-22 | 185-200 | 100 | 120 | 175 | 210 | ||||||||

| M | 70 | 6-16 | 105 | 130 | 160 | |||||||||||

| F | 54 | 5-16 | 80 | 90 | 110 | 135 | 160 | |||||||||

| CCH667D | EC | 133 | 13-26 | 250-280 | 280 | 310 | 340 | 370 | 390 | |||||||

| C | 133 | 10-26 | 210 | 280 | 31 | 340 | 370 | 390 | ||||||||

| M | 89 | 6-19 | 130 | 168 | 215 | 260 | 290 | |||||||||

| F | 70 | 6-13 | 130 | 168 | 215 | |||||||||||

| CCH684D | EC | 203 | 16-26 | 400 | 510 | 600 | 630 | 680 | ||||||||

| C | 178 | 13-26 | 455 | 488 | 552 | 600 | 620 | |||||||||

| M | 133 | 10-19 | 355 | 420 | 460 | 530 | ||||||||||

| F | 105 | 6-16 | 220 | 310 | 375 | 428 | ||||||||||

1.The capacity is total tons per hour passing through crusher at open circuit when crushing medium and below hardness material and bulk density with 1.6x103kg/m3. Capacities are relative to physical character and type of feeding, feeding size and composition and so on.

2.CCH651(D)and CCH684(D)standard configuration includes discharging opening of hydraulic locking and hydraulic motor adjustment, and you can choose CCH639(D),CCH651(D)as matching products.

Dear friends :

Welcome to Zhengzhou Yifan Machinery Co.,Ltd. To contact us through our website,

Please feel free to give your inquiry in the form below.We will reply you with details ASAP.

NEXT:Sand Making Machine