Typical Craft

» Basalt Aggregate for Express Highway Processing Chart

» Manufactured Sand Processing Chart

» Advanced Process and Equipment of Glass Raw Materials

» The Mobile Crushing and Screening Plants

» SS Series Sand Collecting System

Stone Crusher Series

» Mobile Crusher

» Mobile Crushing-Screening Plant

» SMH Hydraulic Cone Crusher

» PE/PEX Series Jaw Crusher

» Vertical Shaft Impact Crushers

» SDF Series Impact Crusher

» PF Series Impact Crusher

» PCH Series Ring Hammer Crusher

» Drying Hammer Crusher

Washer - Feeder - Screen

» ZSW Series Vibrating Feeder

» GZT Series Vibrating Feeder

» XL Series Sand Washer

» XS Series Sand Washer

» YK Series Incline Vibrating Screen

» ZK Series Vibrating Screen

» Sand Collecting System / Sand Collector

» GZG Series Auto-synchronous Vibrating Feeder

Basalt Aggregate for Express Highway Processing Chart

In the highway asphalt concrete road surface, both SMA and Super pave technology assign high requirement of the shape and rank of aggregate. Especially to the content of needle plate type in the basalt, the former impact crusher processing chart cannot meet the requirement any longer. Therefore, our company put up the newest crushing and screening processing chart-VI series Vertical Shaft Impact Crusher to meet the need. The high-quality aggregate produced by this production line was widely used in SMA road surface of Shenyang-dalian highway.

Basalt Aggregate for Express Highway Processing Chart:

Basalt Aggregate for Express Highway Processing Chart:

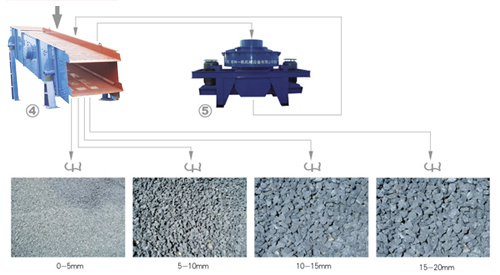

1. ZSW Series Vibrating Feeder

2. PE/PEX Series Jaw Crusher

3. PF Series Hard Rock Impact Crusher or Cone Crusher

4. YK Series Incline Vibrating Screen

5. VI Series Vertical Shaft Impact Crushers

The features of the processing:

1. The quality of the product is very high. Content of needle plate type is no more than 5%. A diabase in Huzhou, Zhejiang province once adopted Jaw Crusher-Impact Crusher. But content of needle plate type is more than 10%, resulting the bad sell of its product. After using VI Series Vertical Shaft Impact Crushers, the content of needle plate type in the product is reduced to 4.7% .

2. The production improves 50% compared with utilizing Impact Crusher as the final processing of crushing.

3. Because we utilize Impact Crusher as the secondary crusher, and Vertical Shaft Impact Crusher consumes little metal, the consumption of wear-parts reduced largely in the whole processing.

TOP

TOP