- CJ Series Jaw Crusher

- Sand Making Machine

- CCH Hydraulic Cone Crusher

- CCS Hydraulic Cone Crusher

- CHP/CHS Impact Crusher

- CCM Hydraulic Cone Crusher

- Vertical Shaft Impact Crusher

- Gyratory Crusher

- Construction waste recycling

- Mobile Jaw Crusher station

- Crawler Screening Crusher

- Mobile Impact Crusher Station

- Mobile Screening Station

- Crawler Mobile cone Crusher

- Mobile Cone Crusher Station

- Crawler Mobile Impact Crusher Station

- Vertical Impact Mobile Crusher

- Crawler Mobile VSI impact crushing plants

- Mobile Teeth Roll Crusher

Detail:Jaw Crusher blocking material will affect the normal operation of the crushing production line, thereby reducing their productivity, jaw crusher for blocking material problem, how to solve it?

Replay:

YIFAN to answer your questions: jaw crusher blocking material causes and solutions.

Jaw crusher jump stop is the main reason for blocking material under the jaw crusher cavity row not too much plot material, withstand dynamic cone, resulting in motor overload jump stop.

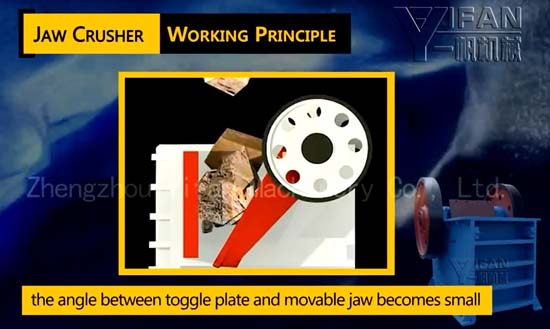

Jaw Crusher Working Principle material crushing

There are usually two cases resulting jump stop:

The first: jaw crusher, high yield, slat conveyors too late to taken away;

The second: downstream equipment jump stop, and the jaw crusher continue crushing. Once this happens, you need to clean up all the material crushing cavity can continue to turn out, time-consuming, generally at least have one hour to complete.

In order to prevent blocking material, we use directly through sound and light indicator indicates pouring. Due to lower operating current jaw crusher cavity and under heavy material conveyor little good correlation, and each material under a multi-cavity caused by jaw crusher jump stop. Therefore, based on the current characteristics of the slat conveyor, developed a solution that is poured in jaw crusher discharge port to install a warning bell and flashing lights, directly connected to the electrical cabinet relay, when the plate conveyor reaches the current value of a set of when the relay, warning lights start flashing, bells are ringing. If the downstream equipment jump stop, when the plate conveyor current is zero, there will be audible and visual alarm alerts. Tramcar driver after receiving the alarm will stop pouring to prevent blocking material.

Crusher blocking material related problems:

How to solve the stone crushing production line blocking material issue?

Dear friends :

Welcome to Zhengzhou Yifan Machinery Co.,Ltd. To contact us through our website,

Please feel free to give your inquiry in the form below.We will reply you with details ASAP.

NEXT:No