- CJ Series Jaw Crusher

- Sand Making Machine

- CCH Hydraulic Cone Crusher

- CCS Hydraulic Cone Crusher

- CHP/CHS Impact Crusher

- CCM Hydraulic Cone Crusher

- Vertical Shaft Impact Crusher

- Gyratory Crusher

- Construction waste recycling

- Mobile Jaw Crusher station

- Crawler Screening Crusher

- Mobile Impact Crusher Station

- Mobile Screening Station

- Crawler Mobile cone Crusher

- Mobile Cone Crusher Station

- Crawler Mobile Impact Crusher Station

- Vertical Impact Mobile Crusher

- Crawler Mobile VSI impact crushing plants

- Mobile Teeth Roll Crusher

Detail:How effective maintenance of jaw crusher? This is the user to buy, buy later will ask the question, is crucial for future use, because the use of scientific and reasonable method of jaw crusher and maintenance can not only prolong the life of the crusher can also improve production efficiency.

Replay:

Jaw crusher maintenance mainly from the following three aspects:

Before starting maintenance

1, should carefully check bearing lubrication condition is good, the bearing bracket connections have enough grease.

2, you should carefully check all fasteners are fully tightened.

3, guards are good, found to be unsafe, should immediately remove it.

4, check whether the ore crushing cavity or other debris, if any, should be immediately eliminated.

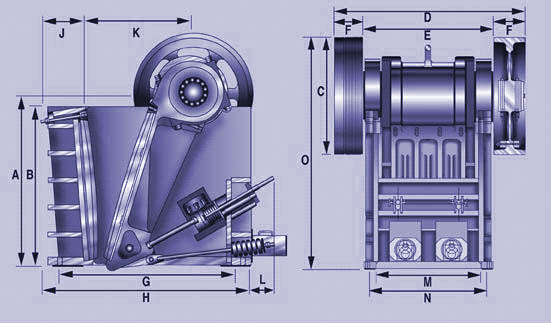

PE 600*900 jaw crusher structure

Maintenance at work

1, upon inspection, proved the machine and the transmission part normal, before starting.

2, the machine can only be started in case of no load.

3, after starting, if found to have abnormal situations, should be immediately stopped, to be identified because eliminate hidden dangers, before starting again.

Lubrication and maintenance

1, the regular and timely attention to the friction surface lubrication, and then, in order to ensure the normal operation of the crusher and prolong life.

2, the machine used for calcium-based grease, the user can also be used depending on the machine position, temperature, and selection of other types of fat other conditions, but must be protected by a well-lubricated bearings.

3, by adding 50-70% of the total bearing, grease, must be replaced every three months. Oil change, clean gasoline and kerosene applications, and carefully clean ball bearing slides.

The article by YIFAN Crusher,Mobile crusher,Crusher Machine YIFAN Machinery Editor: http://www.yifancrusher.com, please indicate the source , little effort , thank you !

Dear friends :

Welcome to Zhengzhou Yifan Machinery Co.,Ltd. To contact us through our website,

Please feel free to give your inquiry in the form below.We will reply you with details ASAP.

NEXT:How to choose cone crusher? Gravel aggregate production line is generally used in what type of cone crusher?