- CJ Series Jaw Crusher

- Sand Making Machine

- CCH Hydraulic Cone Crusher

- CCS Hydraulic Cone Crusher

- CHP/CHS Impact Crusher

- CCM Hydraulic Cone Crusher

- Vertical Shaft Impact Crusher

- Gyratory Crusher

- Construction waste recycling

- Mobile Jaw Crusher station

- Crawler Screening Crusher

- Mobile Impact Crusher Station

- Mobile Screening Station

- Crawler Mobile cone Crusher

- Mobile Cone Crusher Station

- Crawler Mobile Impact Crusher Station

- Vertical Impact Mobile Crusher

- Crawler Mobile VSI impact crushing plants

- Mobile Teeth Roll Crusher

Detail:Jaw crusher general process of using what type of lubricating grease? How long jaw crusher to change the lubricant?

Replay:

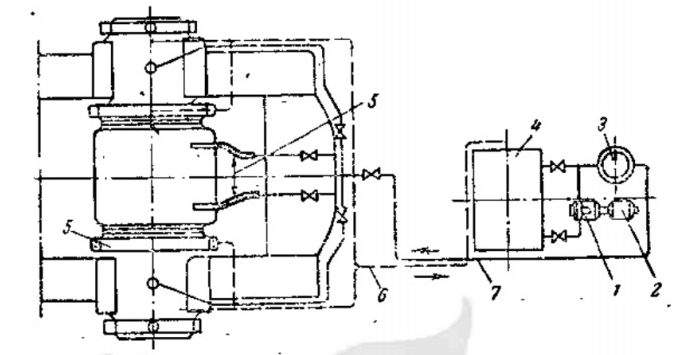

Jaw crusher lubrication system

[1] always pay attention and timely manner lubricated friction surface was working to ensure the normal operation of the machine and extend its life.

[2] jaw crusher used lubricating grease should be based on the location of use, the temperature conditions may be, under normal circumstances using calcium, sodium and calcium sodium based grease.

[3] adding grease within the bearing for about 50% of volume of space, every 3 to 6 months to replace a. Oil change, application of clean gasoline or kerosene cleaning roller bearing raceway.

[4] Before starting jaw crusher, thrust plate and thrust plate between supports should be injected into the right amount of grease.

Dear friends :

Welcome to Zhengzhou Yifan Machinery Co.,Ltd. To contact us through our website,

Please feel free to give your inquiry in the form below.We will reply you with details ASAP.

NEXT:YIFAN large JC jaw crusher can effectively crushing limonite