- CJ Series Jaw Crusher

- Sand Making Machine

- CCH Hydraulic Cone Crusher

- CCS Hydraulic Cone Crusher

- CHP/CHS Impact Crusher

- CCM Hydraulic Cone Crusher

- Vertical Shaft Impact Crusher

- Gyratory Crusher

- Construction waste recycling

- Mobile Jaw Crusher station

- Crawler Screening Crusher

- Mobile Impact Crusher Station

- Mobile Screening Station

- Crawler Mobile cone Crusher

- Mobile Cone Crusher Station

- Crawler Mobile Impact Crusher Station

- Vertical Impact Mobile Crusher

- Crawler Mobile VSI impact crushing plants

- Mobile Teeth Roll Crusher

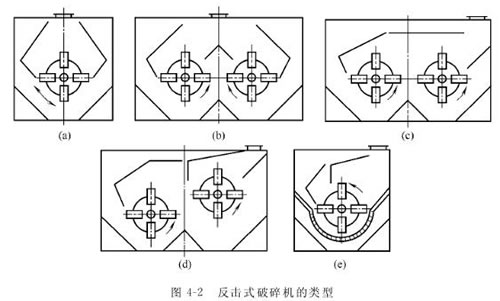

Impact Crusher working principle and application performance characteristics

Nutation of the impact crusher is welded to the outer frame can be rotated hammer rack, the drive system of the power transmitted to the rotor so that the rotor rotating to reach the normal speed after the hammerhead in the radial radial centrifugal force was upright on the hammer rack , this time can be added to the material to be crushed.

Stones into the feed port, after counterattack Edition, by the fast rotating of the hammer blow crushing; material after being hit acquire kinetic energy to be accelerated, and the strike plate at a higher speed to the impact, or to each other with the material impact the formation of impact crusher; The broken material into the the curved screen area, less than the grate gap small leakage of material from the sieve gap broken product. Small part has not yet reached the required dimension of the coarse material on the screen surface by the hammer impact crusher, and hammer and the arcuate sieve relative role shear crushing (grinding stripping broken), until it reaches the required dimension from grate The seam discharged.

Hammer free-hanging, when the encounter difficult broken object or material is too large or piece of metal to enter, hammerhead along the pin rotary recline let non-broken, in order to avoid damage to the mechanical parts, this is impact crusher safety device role. Further, in the shaft is also equipped with a dedicated safety device, insurance pins in overload is cut, so that the motor and the connection of the rotor of the crusher disengaged the sky protective effect.

Hammer free-hanging, when the encounter difficult broken object or material is too large or piece of metal to enter, hammerhead along the pin rotary recline let non-broken, in order to avoid damage to the mechanical parts, this is impact crusher safety device role. Further, in the shaft is also equipped with a dedicated safety device, insurance pins in overload is cut, so that the motor and the connection of the rotor of the crusher disengaged the sky protective effect.

Impact Crusher through the work of agencies of the impact of feed blocks or material to block each other impact crushed. Due to the high-speed impact energy, so that the material along its fragile surface broken in the free state, and thus particularly suitable for brittle materials such as crushed limestone impact crusher.

Impact Crusher materials i, i = 10 to 50, can be used for coarse crushing, crushed, crushing Crusher, Impact Crusher can be equivalent to the primary crusher crusher or in broken broken machine and crushing crusher two crusher used in tandem. As fine crusher production obtained d = 0 to 10mm product granularity. Feeding the coarse crushed material sizes up to 2500mm, feeding size is generally 500 ~ 600mm, you can get a product particle size of between 25 ~ 35mm, crushing than i was about 20.

1, Simple and compact structure, easy operation and maintenance.

2, Uniform particle size, the degree of over-crushing small sieve over.

3, Impact Crusher major the peel role to shock and carrot grinding crushed materials, high crushing efficiency, small unit power consumption, large production capacity. The product particles Duocheng cuboidal.

4, Suitable for processing brittle materials and the medium can be broken, not processing difficult to crush resistance, viscoplastic, wet materials. Of broken sticky and wet materials when the moisture content of the material is more than 15%, and prone to the grate bars sieve clogging and greatly reduce production capacity.

5, The hammerhead, pads need regular maintenance to replace the hammer replacement to adjust the balance.

6, Sieve gap is easy to plug the broken water larger materials need to be periodically cleaned out.

Dear friends :

Welcome to Zhengzhou Yifan Machinery Co.,Ltd. To contact us through our website,

Please feel free to give your inquiry in the form below.We will reply you with details ASAP.

NEXT: There are three main impact crusher crushing effect