- CJ Series Jaw Crusher

- Sand Making Machine

- CCH Hydraulic Cone Crusher

- CCS Hydraulic Cone Crusher

- CHP/CHS Impact Crusher

- CCM Hydraulic Cone Crusher

- Vertical Shaft Impact Crusher

- Gyratory Crusher

- Construction waste recycling

- Mobile Jaw Crusher station

- Crawler Screening Crusher

- Mobile Impact Crusher Station

- Mobile Screening Station

- Crawler Mobile cone Crusher

- Mobile Cone Crusher Station

- Crawler Mobile Impact Crusher Station

- Vertical Impact Mobile Crusher

- Crawler Mobile VSI impact crushing plants

- Mobile Teeth Roll Crusher

Limestone production line (solutions)

Demand Analysis:

Crushing materials: Limestone

Production Capacity: 100 t / h

Feed size: <400mm

Discharge size :50-100mm

Limestone Production Line process solutions:

Hopper + vibrating feeder + jaw crusher + vibrating screen + belt conveyor + electronic control system

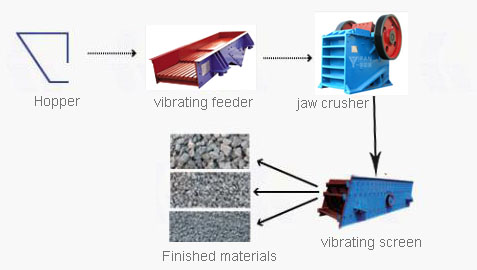

Limestone production line configurations simple flow chart:

Limestone production line process details:

[1]. Chunks of stone by the Hopper evenly sent by the vibrating feeder jaw crusher for primary crushing;

[2]. Crushed stone sent by the belt conveyor vibrating sieve, sieve out the stones of different levels of granularity to meet the size requirements of stones were taken from the finished product conveyor belt stockpiles;

[3]. Do not meet the size requirements of large stones by the belt conveyor to return to the jaw crusher for re-crushing to form a closed loop several times.

[4]. According to environmental needs, can be equipped with dust removal equipment.

Zhengzhou Yifan Machinery Co., limestone production line configuration features:

[1]. Ahigh degree of automation, the entire production line equipment, in addition to starting, stopping and routine maintenance, almost no manual operation.

[2]. The production of high efficiency, low operating costs, high return.

[3]. The finished stones uniform particle size, grain shape is good, powder output is low.

[4]. The use of advanced electronic control system to ensure that the entire production line safe, reliable operation.

Limestone Crusher Installation Notes:

[1] In order to not damage the foundation in basic upper guard must cover the items owned by the user.

[2]. Installation to the fixed contact surfaces coated with dry oil, the active surface coated with thin oil.

[3]. Breakers must be installed on a solid reinforced concrete, based on the depth of the user base according to local geological conditions.

[4] In order to avoid accumulation of the crushed ore, the lower base must have sufficient space for installation and transportation equipment.

[5]. Before installing the number of parts to be counted. Check with the individual parts machined surface with clear thread in the loading and unloading of the damage caused, and remove the packaging process when applied to the protective coating on the surface as well as in handling falling behind in the dust and dirt and so on.

Limestone production line operation maintenance Note:

[1]. Before mounting the number of parts to be counted. Check with the individual parts machined surface with clear thread in the loading and unloading of the damage caused, and remove the packaging process when applied to the protective coating on the surface as well as in handling falling behind in the dust and dirt and so on. Site selection to fully consider the wind, rivers and surrounding buildings on the possible impact of equipment

[2]. Before installing the number of parts to be counted. Check with the individual parts machined surface with clear thread in the loading and unloading of the damage caused, and remove the packaging process when applied to the protective coating on the surface as well as in handling falling behind in the dust and dirt and so on. Going to be as smooth, dense, avoiding sand production line in use due to the weight of large, intense vibrations and other causes tilting equipment, infrastructure collapse, resulting in unnecessary rework

Waste and economic loss.

[3]. Before installing the number of parts to be counted. Check with the individual parts machined surface with clear thread in the loading and unloading of the damage caused, and remove the packaging process when applied to the protective coating on the surface as well as in handling falling behind in the dust and dirt and so on. Crusher (limestone crusher) maintenance performance directly determines the quality of life of limestone production line and efficiency, so do jaw crusher, vibrating feeder, vibrating screen machine maintenance, such as avoiding prolonged overload running in a timely manner machine lubrication and maintenance and so on.

Dear friends :

Welcome to Zhengzhou Yifan Machinery Co.,Ltd. To contact us through our website,

Please feel free to give your inquiry in the form below.We will reply you with details ASAP.

NEXT:150 t / h iron ore sand Solutions and Process

- 150 t / h iron ore sand Solutions and Process

- Limestone production line (solutions)

- Perlite crushing production line processes

- River gravel sand production line

- Quartz sand production line

- Pebbles sand production line

- Basalt stone production line

- Limestone stone production line

- limestone production line

- Tailings sand making production line

- Expressway aggregate processing production li

- Mechanism of sand production line process

- Sand and gravel production line

- Gravel production line

- Stone production line

- Sand production line